Modular weighing system, consisting of 2/3/4 portable platforms and WIN 11 indicator in transportable aluminum suitcase.

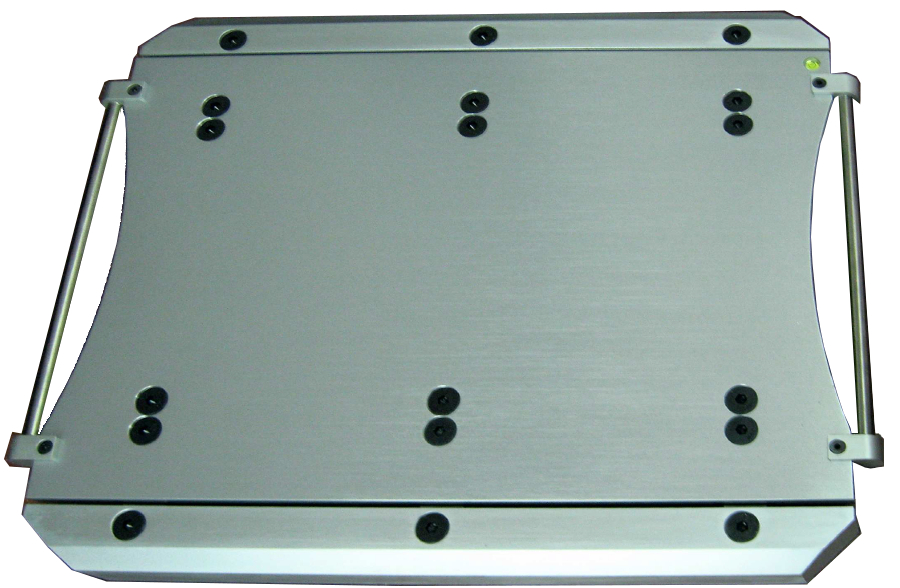

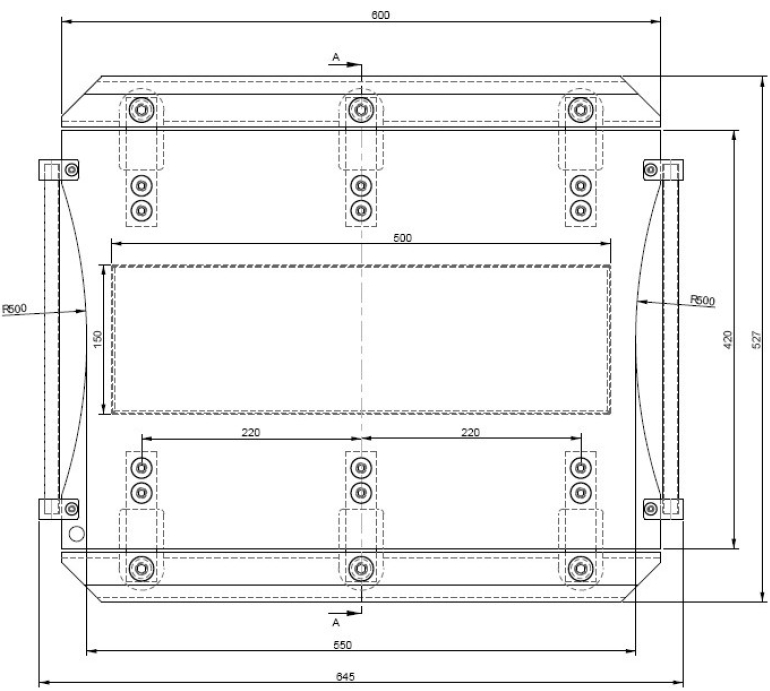

Low profile platforms with several capacities, construction of high strength anodized white aluminum alloy. Double up / down ramp with a wide support base for immediate vehicle positioning equipped with anti-slip rubber. Spirit level for reference and easy carrying handles for transportation.

Individual display of each single platform or the sum of all platforms with total weight visualization. Platforms and indicator wireless connected. The display comes in portable, handy and durable carrying case. Powered by internal rechargeable batteries, supplied with charger, battery autonomy about 200 h.

![]() Click to enlarge image

Click to enlarge image

| Power supply | 220 V ac / 24 V dc | |

| Operating temperature | -10 / +50 °C (14 / 122 °F) | |

| Storage temperature | -20 / +60°C (-4 / +140°F) | |

| Overall dimensions | 600 x 527 x 53 mm / 23.6 x 20.7 x 2.1 in | |

| Frequency | 866-868 MHz | |

| Num. RF Channels | 7 selectable by DIP switch | |

| Num. Network address | 15 selectable by DIP SWITCH | |

| Average radius of coverage | 50 m | |

| Average battery life | ~200 h | |

| Platform dimensions | 600 x 527 x 53 mm / 23.6 x 20.7 x 2.1 in | |

| Platform material | High strength aluminum | |

| Platform weight | 25 kg / 55 lbs | |

| Load cells material | Stainless steel | |

| Load cells capacity | 2,5, 5, 10 t | |

| Cells number (1 platform) | 6 | |

| Briefcase overall dimensions | 400 x 300 x 200 mm / 15.7 x 11.8 x 7.9 in | |

| Briefcase weight | 5 kg / 11 lbs | |

General precautions to be followed in the installation and assembly of load cells: